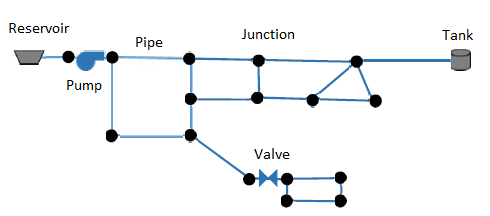

EPANET models a pipe network as a collection of links connected to nodes. The links represent pipes, pumps, and control valves. The nodes represent junctions, tanks, and reservoirs. The figure below illustrates how these objects can be connected to one another to form a network.

|

Junctions have a user-supplied water withdrawal rate (i.e., consumer demand) associated with them. Tanks are storage units whose water level changes over time. Reservoirs are boundary points where a fixed hydraulic head applies.

Pipes have a length, diameter and roughness coefficient that determines their head loss as a function of flow rate. Pumps have either a constant power rating or a head curve that determines the head they add as a function of flow rate. Valves are used to regulate either flow or pressure. Controls can be applied to completely open or close a link or to adjust its setting (pump speed or valve setting).

In addition to these physical objects an EPANET model can also contain the following data objects:

- time patterns that allow demands, quality source strength and pump speed settings to vary at fixed intervals of time

- data curves that describe relationships between two quantities, such as head versus flow for pumps and volume versus water level for tanks

- simple controls that adjust a link's setting (such as a pump's status) based on node pressure, tank level, elapsed time, or time of day

- rule-based controls that consist of one or more premises that if true result in one set of actions being taken and if false result in a different set of actions being taken

- water quality sources that introduce a chemical constituent into the network at specified nodes.

An EPANET model also contains a number of analysis options that specify:

- the project's flow units which in turn determines its unit system (US or SI)

- the formula used to compute pipe head loss as a function of flow rate

- whether to use a demand driven or a pressure driven analysis

- hydraulic convergence criteria and water quality tolerances

- time steps used for hydraulic, water quality and reporting

- the type of water quality analysis to perform (chemical reaction, source tracing or water age)

- global values for energy usage parameters that can be overridden for individual pumps.

Please refer to the EPANET 2 Users Manual for more information on EPANET's data model.